Services

I support the full lifecycle of laser sources and laser-based systems and processes—from source selection and optical design to process development and production integration. My experience includes working with laser sources such as: ultrafast laser sources (picosecond, femtosecond), nanosecond lasers (solid-state, excimer) as well as high-power kilowatt fiber laser sources and their process applications of materials such as diamond, Nitinol, semiconductors, metals, glass, polymers, thin films, and many more.

My beam delivery system expertise spans flying optic gantries, F-theta galvo scanners, mask projection optics, diffractive optics, beam shaping, quad-cell beam pointing stabilization, AOM-based beam splitting, and 5-axis scanning systems. I offer rigorous laser source evaluation, system design, system assembly and alignment, precision calibration, process characterization, and documentation for scalable manufacturing.

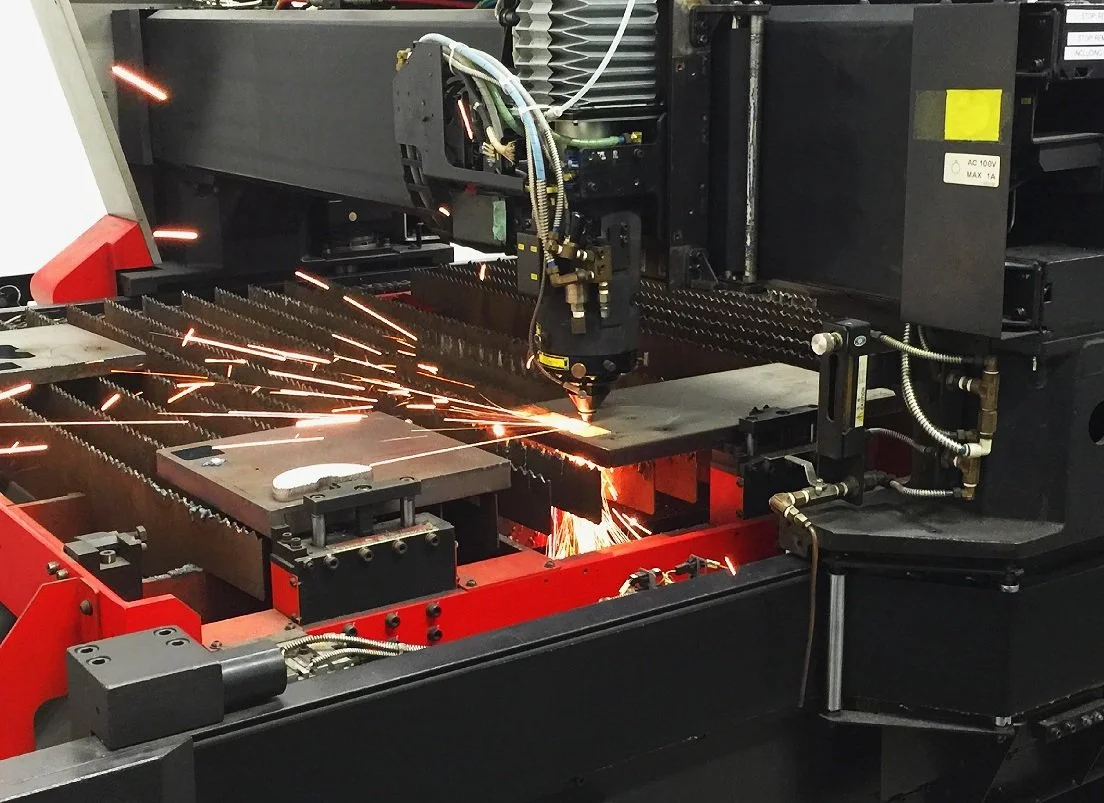

Macromachining of Thick Stainless Steel (Amada)

@ Osman A. Ghandour & Lumentum

Laser Systems & Source Expertise

Evaluation, testing, and characterization of nanosecond and excimer laser sources, ultrafast laser sources (picosecond and femtosecond), and high power fiber laser sources.

Laser system design and integration for R&D and production

Routine and advanced maintenance, troubleshooting, and alignment

Laser safety and power delivery

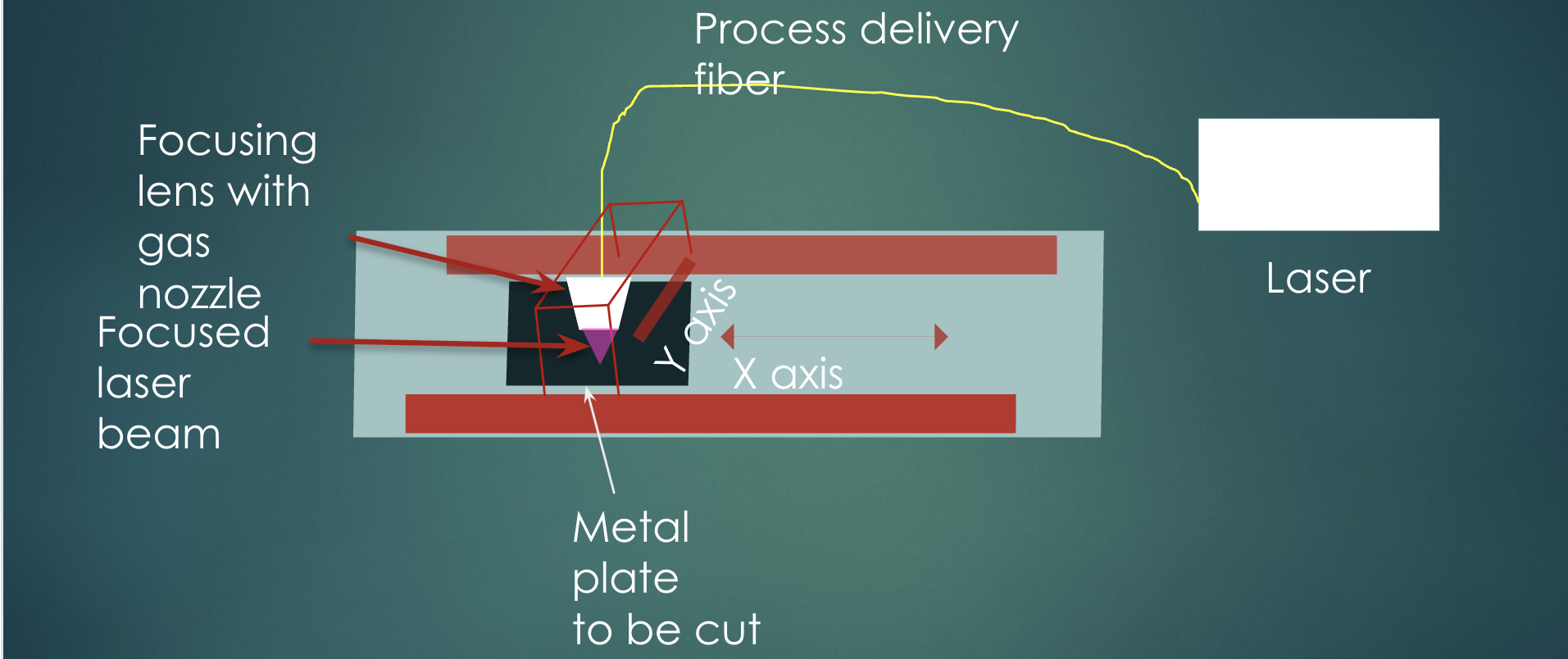

Macromachining applications using 2-12 kW fiber lasers – System Schematic

@ 2025 Osman A. Ghandour & Lumentum

Beam Delivery Engineering

Design and implementation of advanced beam delivery systems, including:

Flying optic gantry and F-theta galvo scanning

Mask projection imaging and diffractive mask focusing

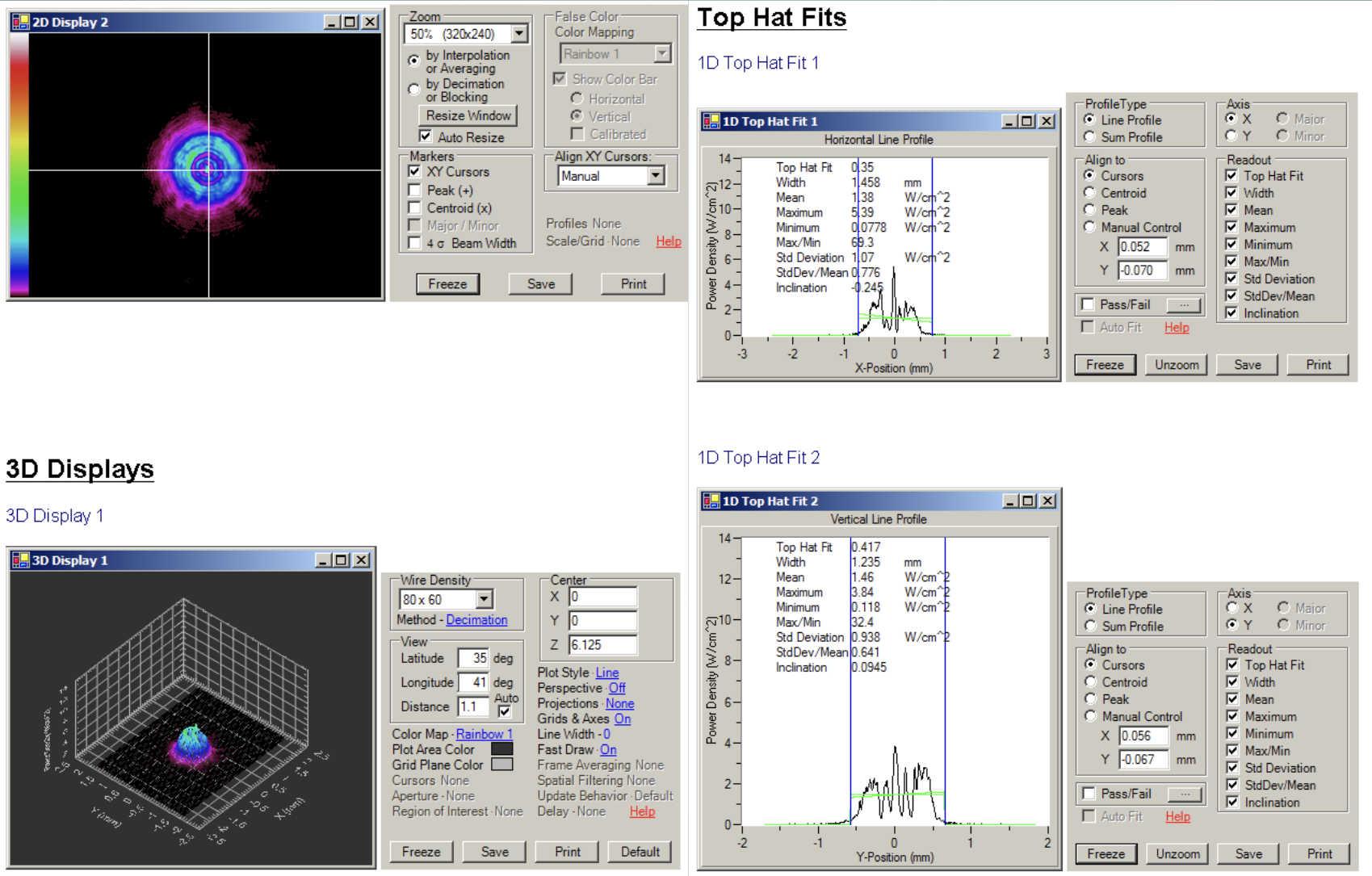

Beam shaping (top-hat, circular, rectangular profiles)

AOM beam splitting and quad-cell beam stabilization

Multi-axis scanning platforms

Laser-based blind via drilling in-line beam quality monitoring

@ 2025 Osman A. Ghandour & Alien Technology

Laser Process Development

Application development for cutting, welding, scribing, drilling, texturing, and patterning. Use of metrology and diagnostic tools for beam profiling, alignment, and material characterization

Material-specific process optimization for diamond, Nitinol metals, semiconductors, polymers, glass, and thin films

Parameter tuning for throughput, quality, and thermal control

Prototype development, scaling strategies, and process documentation

Development of QC and test protocols to support production ramp-up

Comprehensive documentation for system configuration, SOPs, and process repeatability

Contact us

I’m confident I can help you find the right solutions. Just fill out the form, and me or my team will be in touch shortly.